Le banc de test accessible dès vos mini-séries : Découvrez notre approche 'maker' abordable

Introduction

Idée reçue : un banc de test, ce n'est que pour les grosses séries !

Ah, la joie du monde de la fabrication électronique ! Même si on aime beaucoup la technologie et son projet et qu’on est ravi de recevoir sa livraison de cartes, lorsqu’il faut passer plusieurs heures à flasher et tester à la main, on avoue se rendre compte du caractère pénible et répétitif de la chose.

C’est là qu’on se met à 💭rêver💭 d’automatisation et d’optimisation… 🤓 un banc de test 🤓 !

On pense souvent qu’un banc de test, c’est pour les gros volumes, mais la réalité est différente. Dans une équipe de makers, on aime se lancer des défis !

Le défi quotidien : tester efficacement les composants, les soudures et la fonctionnalité.

Nombre d’entre nous l’ont vécu : ce moment où on a tout un tas de cartes électroniques devant soi, prêtes à être testées et flashées avant de les incorporer dans le produit final. C’est impératif de les tester entièrement, histoire de ne pas avoir de mauvaises surprises en fin de parcours.

Pourquoi un banc de test sur mesure ?

Automatiser la chose, et optimiser son temps

Les étapes de tests manuels peuvent rapidement devenir répétitives. Si on démarre en se disant que ça va aller, plein d’optimisme et de motivation, pensez-y une seconde, pensez-y vraiment !!

Avant d’alimenter la carte, on vérifie les courts-circuits potentiels :

- Il faut donc attraper le multimètre positionner les sondes sur les points de tests, la carte électronique est un peu bancale alors ce n’est pas simple.

Puis une fois alimentée, on mesure les niveaux de tension,

- On lance l’alimentation de laboratoire et à nouveau on vient cherche les point tests en espérant lire 3,3V et 12V sur le multimètre.

Tout cela à la main, encore et encore. C'est éreintant et sujet à erreurs. Vite, un banc de test !! Il faut automatiser tout ça !

Puis la programmation :

- On bouge la souris pour sortir de veille, on branche le programmateur s’il y à un connecteur, sinon on maintient le câble de programmation en pression sur la carte le temps de télécharger le programme. Et on attend de lire « success » dans les Log. Patience …

Et enfin on vérifie la fonctionnalité générale.

- Chaque projet est différent alors ça pourrait être : brancher le moteur que la carte doit activer, vérifier une lecture NFC, ou la connexion en BLE à un smartphone, la diffusion de son , etc.

La magie du processus "Maker"

Identification des besoins

Commençons par analyser cette carte destinée à être flashée et testée. Identifions d’abord les points de test. Listons ensuite toutes les fonctions que nous pouvons vérifier. C’est à partir de cette base que nous concevrons le banc de test approprié.

C’est également le moment d’évaluer les ressources techniques et de trancher entre ce qui doit être automatisé et ce qui peut rester sous la responsabilité de l’opérateur. Prenons un exemple : dans notre situation, il aurait été possible d’intégrer un petit servo-moteur pour activer le bouton à tester. Toutefois, pour des raisons budgétaires liées au banc de test, c’est à l’opérateur de le faire. Sa présence est d’ailleurs nécessaire pour confirmer que la LED s’allume. Si le budget l’avait permis, nous aurions pu développer un système de détection de l’éclairage de la LED, utilisant par exemple une photodiode. Il est essentiel de définir précisément les besoins et d’adapter la solution technique au budget alloué pour le banc de test.

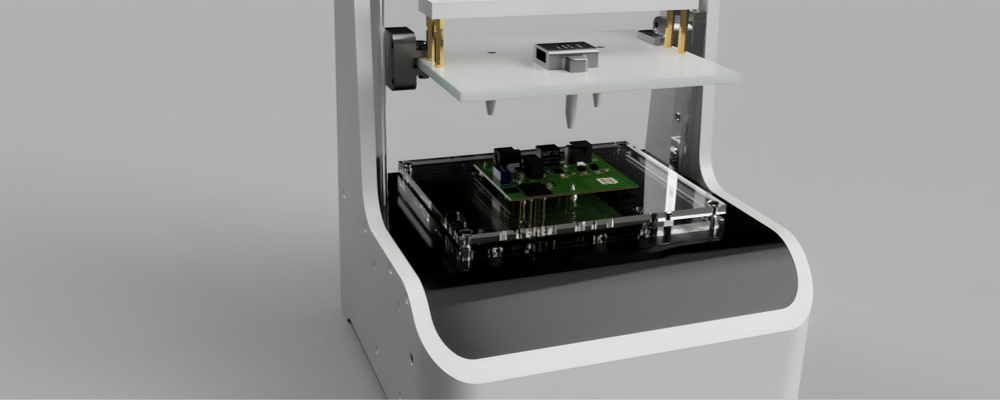

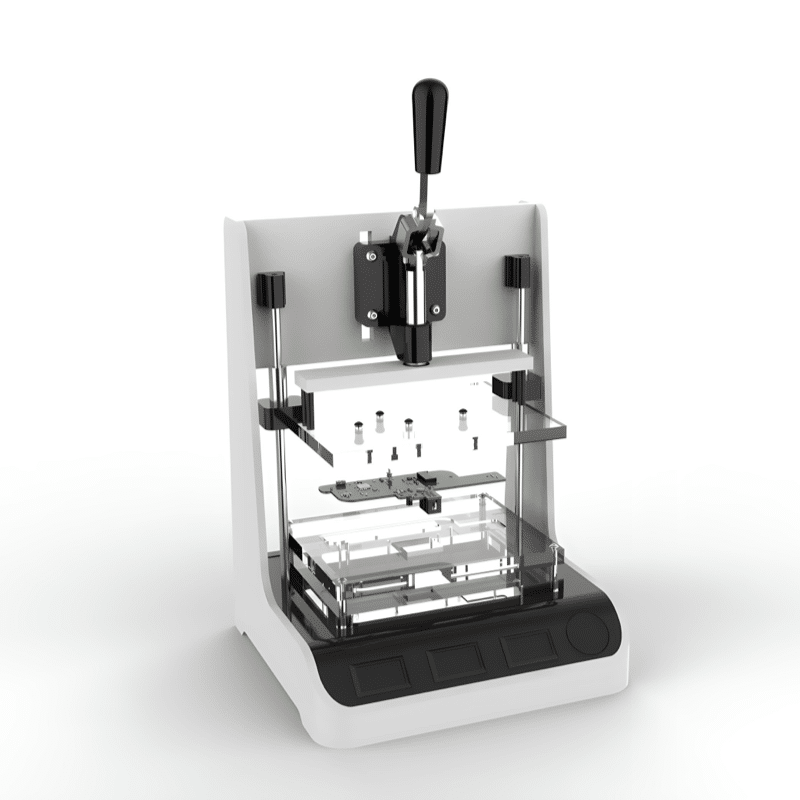

Conception Technique

Le cœur du maker réside dans l’art de mobiliser des ressources existantes pour les recombiner à sa guise. Dans un banc, nous pouvons trouver divers ressources tels qu’une Raspberry Pi, un lecteur de code à barre USB, un lecteur NFC USB et une sonde Segger. Cependant, il y a un composant que nous concevons sur mesure : un PCB qui accueille les Pogopin. Ces derniers établissent le contact avec les points de test des cartes à examiner. Pour les pièces qui ne sont pas disponibles sur le marché de l’électronique, nous avons la possibilité de les créer grâce à des outils contemporains comme l’impression 3D, la découpe laser ou encore les CNC.

Assemblage et mise au point

Chez BLUEGRioT, nous sommes convaincu, que la conception est autant une question d’esthétique que de fonctionnalité. Le châssis du banc de test BLUEGRioT alliant innovation et efficacité, a été designé de manière à accueillir une variété de composant, et être modulaire

Cas d'usage : exemple banc de test

Une immersion plus profonde : détails sur un banc de test

Après toutes ces explications générales, plongeons-nous dans un exemple concret de banc de test.

Nous avons préparé une vidéo qui illustre bien le processus et le gain de temps réel grâce au banc de test.

La preuve par l'image : La vidéo comparative Lucas Vs Mehdi

1. Les protagonistes : « A gauche Lucas, opérateur qui profite du banc de test, à droite Mehdi opérateur muni de son alimentation de laboratoire d’un multimètre et de son ordinateur. »

2. Gestion de la traçabilité : « En plus des tests à réaliser, les deux opérateurs doivent gérer la traçabilité de ces tests, c’est-à-dire que Lucas « bip » un simple QR-Code à la manière d’un hote de caisse, alors que Mehdi doit noter dans un fichier, le numéro de série de la carte qui va être testée et flashée, la version du hardware, et ensuite cocher « pass » ou « fail » à chacun des tests effectués, pour tracer les potentielle non-conformité. »

3. Risques d’erreurs : « Pour Mehdi, chaque étape, chaque test, est une opportunité pour une erreur, un oubli, une saisie incorrecte. Sans un banc de test, le processus est non seulement fastidieux, mais il expose également le projet à un risque d’erreur accru. »

4. Esprit compétitif vs Démonstration : « Nous remarquerons que Mehdi est dans un esprit de compétition, il s’applique à aller vite et efficacement. Là ou Lucas persuadé d’avoir gagné d’avance, effectue les 4 gestes qui lui sont demandés avec une lenteur déconcertante, dans un esprit de démonstration digne d’un lièvre devant une tortue. »

5. Comparatif des temps : « Résultat du test 1’36 pour jouer le plan de test avec le banc, 3’46 pour l’opérateur sans banc de test. »

6. Optimisation avec le banc de test : « Le plus marquant est que l’opérateur avec le banc de test (Lucas) n’a quasiment rien à faire, il se contente de respirer lentement en regardant dans le vide, il pourrait donc paralléliser des tâches. et pourquoi pas aisément travailler avec 2 ou 3 bancs de tests pour optimiser davantage.

Combien ça coûte de faire un banc de test sur mesure ?

BLUEGRioT a réalisé des banc de test de flashage et de mesure, allant de 6000€ à 60000€. C’est le juste milieu qui est crucial ici. Il faut peser le coût versus le bénéfice potentiel.

Si vous engagez 10.000€ dans un banc de test pour une production de 500 cartes à 25€, l’investissement semble peu rentable s’il est basé uniquement sur l’économie des rebus pour non-conformité.

Cependant, il est important de considérer d’autres facteurs potentiels, tels que:

- La réduction du temps de test et donc des coûts de main-d’œuvre.

- L’amélioration de la qualité perçue par les clients en raison d’une diminution des défaillances.

- La capacité d’utiliser le banc pour tester d’autres produits ou versions futures.

- La réduction des coûts indirects liés aux erreurs humaines et aux retours clients.

C’est pour ces raisons que nous persistons et signons : Le banc de test n’est pas reservé qu’au grande séries !

J’en veux pour exemple notre toute dernière production de 250 cartes pour le projet Reyouzz !

Mise à jours du 10/04/2024

A près avoir reçu nos nouveaux Raspberry Pi 5, nous n’avons pas pu résister à l’envie de les tester sur notre banc de test. Sans changer nos paramètres habituels, nous avons lancé nos tests sur ce nouveau hardware.

Les resultats ?

- Performance quadruplée, sans compromis sur la précision ou l’optimisation du temps.

- Plus rapide et plus fort, le Pi 5 est un véritable boost pour nos tests sur mesure… Avec des temps de traitement réduits et une efficacité accrue, nous sommes plus équipés que jamais pour concrétiser nos/vos idées les plus ambitieuses et tout cela plus rapidement grâce au banc de test.